Concrete is a widely used versatile material in construction but has challenges. The most common problems encountered with concrete involve cracks and crazing, which can compromise concrete structures’ structural integrity and aesthetic appeal. It is important to understand the causes of these problems, and is essential for architects, engineers, and construction professionals to implement adequate preventive measures.

What Is Concrete Leveling and Where Do You Need It?

Concrete leveling, or slab leveling or concrete lifting, is used to raise or level uneven concrete surfaces. There are several reasons why concrete leveling may be needed:

- Uneven Settlement: Over time, the ground beneath a concrete slab may settle unevenly, leading to areas of the slab sinking or becoming unstable. This can occur due to soil erosion, soil compaction, or changes in moisture levels.

- Improving Safety: Uneven concrete surfaces can create tripping hazards. Concrete leveling is often done to eliminate these uneven areas and create a safer environment, especially in high-traffic areas like sidewalks, driveways, and walkways.

- Preserving Structural Integrity: Uneven settling of concrete can affect the structural integrity of buildings and other structures. Concrete leveling helps prevent further damage and ensures the concrete remains stable and structurally sound.

- Cost-Effective Solution: Compared to the cost of completely replacing a concrete slab, leveling is often a more cost-effective solution. It allows property owners to address the issue without the expense and inconvenience of a complete replacement.

- Restoring Aesthetics: Uneven concrete surfaces can be unsightly and negatively impact the aesthetics of a property. Concrete leveling helps restore the affected areas’ smooth and visually appealing appearance.

- Preventing Water Damage: Uneven concrete can lead to water pooling in certain areas, contributing to water damage. Leveling the concrete helps ensure proper drainage and prevents water from collecting in unwanted areas.

- Enhancing Property Value: Maintaining even and well-maintained concrete surfaces adds to a property’s overall curb appeal and value. Concrete leveling is a proactive measure that contributes to property maintenance and improvement.

In summary, concrete leveling is a practical solution to address uneven surfaces, improve safety, preserve structural integrity, and enhance a property’s overall appearance and value.

What Are the Most Common Concrete Problems?

Let’s delve into the most common concrete problems and the underlying causes of cracks and crazing.

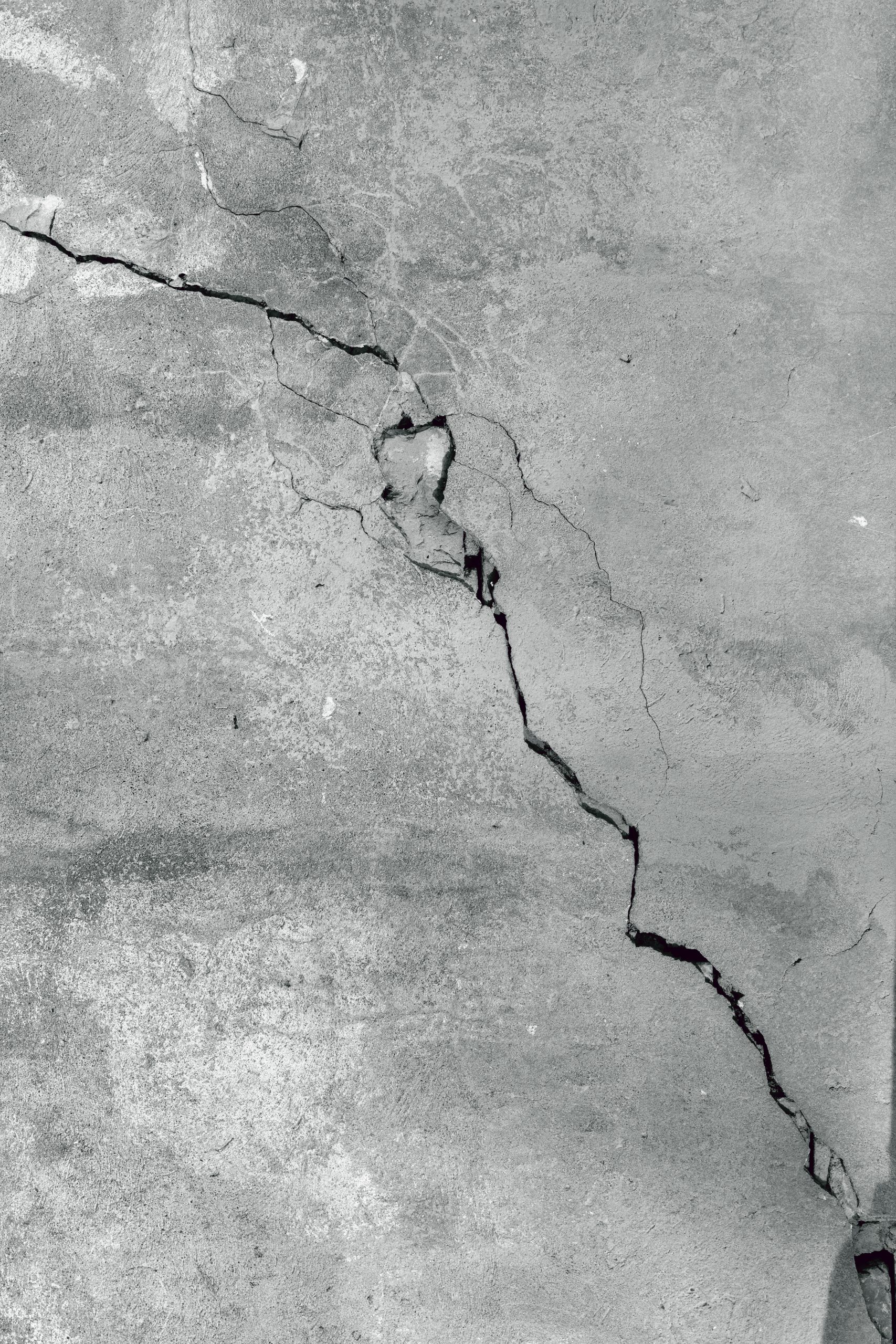

Cracking:

Cracking is the most prevalent issue in concrete structures. These cracks can manifest in various forms, including shrinkage, thermal, and structural. Shrinkage cracks occur during the drying and curing, while thermal cracks result from temperature differentials. Structural cracks may result from excessive loads, poor design, or inadequate construction practices.

Crazing:

Crazing refers to forming a network of fine cracks on a concrete surface, resembling a spider web. It is a surface defect often associated with the concrete mix and curing conditions. Crazing can impact the aesthetics of concrete surfaces, particularly in decorative applications.

Spalling:

Spalling is the chipping or flaking of concrete surfaces, often caused by freeze-thaw cycles, corrosion of reinforcement, or the use of low-quality aggregates. It weakens the concrete and exposes the underlying reinforcing steel to the elements, leading to further deterioration.

Scaling:

Scaling involves the loss of the outer layer of concrete, resulting in a rough and pitted surface. This problem is often associated with deicing salts in cold climates. The salts can penetrate the concrete, leading to freeze-thaw damage and scaling.

Efflorescence:

Efflorescence is a white, powdery deposit on the surface of concrete. The primary cause is the migration of soluble salts to the surface through capillary action. The salts are left behind when the water evaporates, creating a characteristic white residue.

AAR occurs when reactive minerals in aggregates chemically react with alkalis in the cement paste, causing a reaction that forms a gel-like substance, causing expansion and cracking. Two common forms of AAR are the alkali-silica reaction (ASR) and alkali-carbonate reaction (ACR).

Corrosion of Reinforcement:

Corrosion is a significant concern in concrete structures, especially those exposed to harsh environmental conditions. When reinforcing steel corrodes, it expands, leading to cracking and spalling. The penetration of chloride ions or carbonation of the concrete can trigger corrosion.

Poor Joint Design:

Improper joint design or inadequate spacing of joints can result in uncontrolled cracking. Joints are essential in concrete structures to accommodate shrinkage, thermal movements, and structural changes. Lack of proper joint design can lead to random cracking, affecting aesthetics and performance.

Poor Workmanship:

Construction practices and workmanship significantly influence the performance of concrete structures. Inadequate compaction, improper curing, and poor finishing can contribute to various problems, including reduced strength, increased porosity, and susceptibility to cracks.

Freeze-Thaw Damage:

In cold climates, repeated freeze-thaw cycles can cause damage to concrete. Water penetrating the concrete pores freezes and expands, exerting pressure on the concrete. This can lead to cracking, scaling, and overall structure deterioration.

Causes of Cracks and Crazing

Inadequate Mix Design:

The concrete mix’s proportion of cement, aggregates, water, and admixtures significantly influences its performance. An inadequate mix design, whether too much or too little of specific components, can lead to problems such as low strength, increased shrinkage, and susceptibility to cracking.

Improper Curing:

It is essential to achieve the desired strength and durability of concrete. Inadequate curing, especially during the initial stages of hydration, can result in rapid drying and increased shrinkage, leading to the formation of cracks.

Excessive Shrinkage:

Shrinkage is a natural property of concrete during the curing process. However, excessive shrinkage can lead to the development of cracks. Low humidity, high temperatures, and inadequate curing can exacerbate this.

Temperature Differentials:

Rapid temperature changes can induce thermal stresses in concrete, resulting in cracking. This is particularly relevant in climates with significant temperature variations between day and night or between seasons.

Overloading and Structural Issues:

Excessive loads, whether static or dynamic, can exceed the structural capacity of concrete. Poor design, inadequate reinforcement, or construction errors can also contribute to structural cracks. Identifying and addressing these issues during the design and construction phases is crucial.

Environmental Exposure:

Harsh environmental conditions, such as exposure to aggressive chemicals, high humidity, or severe weather, can accelerate concrete deterioration. Corrosive substances can penetrate the concrete matrix, leading to cracks and other problems.

Aggressive Aggregates:

The type and quality of aggregates used in concrete play a significant role in its performance. Reactive aggregates, containing minerals susceptible to alkali-aggregate reaction, can lead to cracking and expansion within the concrete.

Insufficient Reinforcement:

Inadequate or poorly placed reinforcement can compromise the tensile strength of concrete. When subjected to tensile forces, concrete is prone to cracking. Proper reinforcement design and placement are essential to enhance the structural performance.

Lack of Expansion Joints:

Expansion joints are crucial to accommodate movements in concrete structures. Concrete may experience uncontrolled cracking without proper expansion joints due to temperature variations, shrinkage, and structural movements.

High Water-Cement Ratio:

An excessive water-cement ratio in the mix can produce a more porous and weaker concrete. Increased porosity makes the concrete more susceptible to environmental factors, leading to cracks, scaling, and other issues.

Conclusion

In conclusion, material properties, construction practices, and environmental factors influence the most common concrete problems, including cracks and crazing. Managing these challenges requires a holistic approach, encompassing a proper mix of design, construction techniques, and maintenance practices. Ongoing research and advancements in concrete technology continue to provide solutions to mitigate these issues and enhance concrete structures’ overall performance and durability.

Choose The Mudjacking Contractors, the experts in resolving concrete problems.